Table of Contents

Laser Cutter Definition and Working Principle

Claire Posted on Mar 05, 2020

What is a Laser Cutter?

Laser cutter is a tool used in a wide range of industries for precision cutting and designing projects.

The laser cutter emits a high powered laser beam to either cleanly cut or etch a specific design on materials such as steel, plastic or wood. It is generally used more for industrial manufacturing applications and the beam will either burn, vaporise or melt away the excess product, leaving a superior finished design or edge.

A laser cutter has settings known as the computer numerical control (CNC), as well as laser optics, which control and direct the laser beam’s intensity for the desired design effect, or the specific cuts required in a manufacturing or design project. The laser beam is generated by a process whereby electrical discharges or a lamp trigger a lasing material within a confined container causing a chemical reaction, resulting in a high powered beam being released. The beam is then reflected using a mirror in a stream of monochromatic light. From the mirror, the light is then directed by fibre optics or mirrors to the work area, with the narrowest point of the beam cutting or making the design etch on the material.

A laser cutting machine is often used in engineering for the precision cutting of components of machines. For industrial applications, a laser cutting machine is often used to cut structural and piping materials and flat sheet material such as metal. The CNC setting can also be changed to etch or engrave all types of designs on metal, wood and plastic. Speciality CAD (computer aided design) software is used to program the CNC and direct it to perform either the cutting, engraving or etching specifications required for the laser cutting project. The size and capacity of the laser cutting machine determines whether it can be used for smaller or larger-scale manufacturing projects.

How Does a Laser Cutter Work?

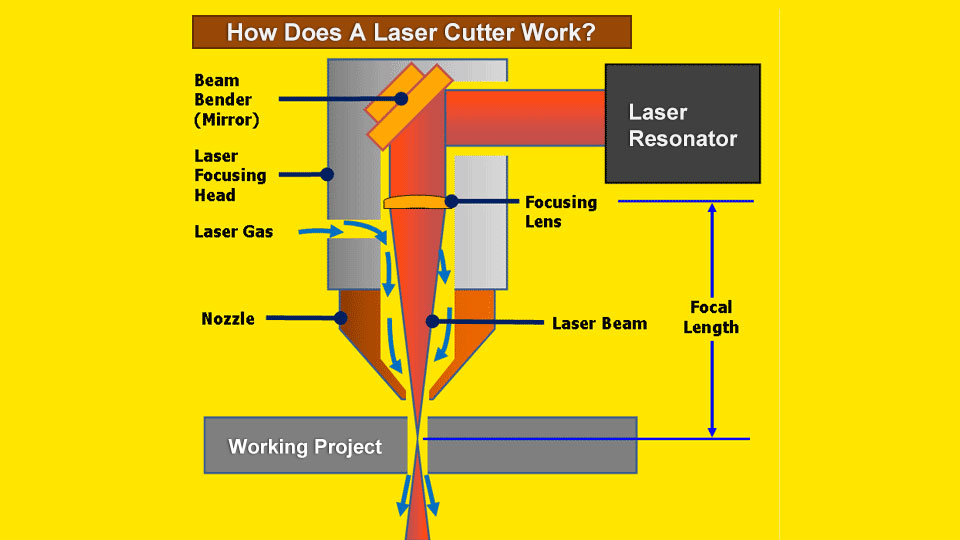

The laser beam is a column of very high intensity light, of a single wavelength, or color. In the case of a typical CO2 laser, that wavelength is in the Infra-Red part of the light spectrum, so it is invisible to the human eye. The beam is only about 3/4 of an inch in diameter as it travels from the laser resonator, which creates the beam, through the machine’s beam path. It may be bounced in different directions by a number of mirrors, or “beam benders”, before it is finally focused onto the plate. The focused laser beam goes through the bore of a nozzle right before it hits the plate. Also flowing through that nozzle bore is a compressed gas, such as Oxygen or Nitrogen.

Focusing the laser beam can be done by a special lens, or by a curved mirror, and this takes place in the laser cutting head. The beam has to be precisely focused so that the shape of the focus spot and the density of the energy in that spot are perfectly round and consistent, and centered in the nozzle. By focusing the large beam down to a single pinpoint, the heat density at that spot is extreme. Think about using a magnifying glass to focus the sun’s rays onto a leaf, and how that can start a fire. Now think about focusing 6000 Watts of energy into a single spot, and you can imagine how hot that spot will get.

The high power density results in rapid heating, melting and partial or complete vaporizing of the material. When cutting mild steel, the heat of the laser beam is enough to start a typical “oxy-fuel” burning process, and the laser cutting gas will be pure oxygen, just like an oxy-fuel torch. When cutting stainless steel or aluminum, the laser beam simply melts the material, and high pressure nitrogen is used to blow the molten metal out of the kerf.

On a CNC laser cutter, the laser cutting head is moved over the metal plate in the shape of the desired part, thus cutting the part out of the plate. A capacitive height control system maintains a very accurate distance between the end of the nozzle and the plate that is being cut. This distance is important, because it determines where the focal point is relative to the surface of the plate. Cut quality can be affected by raising or lowering the focal point from just above the surface of the plate, at the surface, or just below the surface.

There are many, many other parameters that affect cut quality as well, but when all are controlled properly, laser cutting is a stable, reliable, and very accurate cutting process.